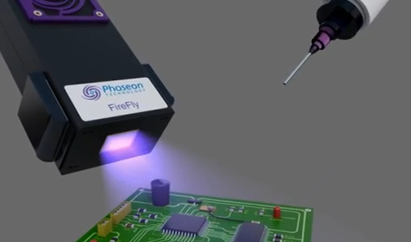

Electrical Components require added protection against the physical stresses our devices are put through today. LED Curing allows manufacturers to modernize this production step. Previously, potting was a long process that required mixing, heating, and staging of the component. Now, UV LED curable potting materials can be cured instantly with Phoseon UV LED curing systems. This technology is a significant improvement over a traditional mercury UV bulb system. Incorporating Phoseon UV LED curing allows the manufacture to streamline production and lower energy costs.

Phoseon field sales and engineering team will ensure you choose the correct curing solution and have industry connections for supply of UV LED curable potting chemistry.

Advantages of UV LED curing systems for potting compounds:

- Replaces 2k potting materials

(epoxy, PURs) - Instant cure, allows for higher production

output, no staging - Less heat, better for sensitive components

Greater cure depth through potting material - No warm up, no ozone, little-to-no curing

maintenance

Learn more about UV LED Curing Solutions for Electronic Potting Compounds