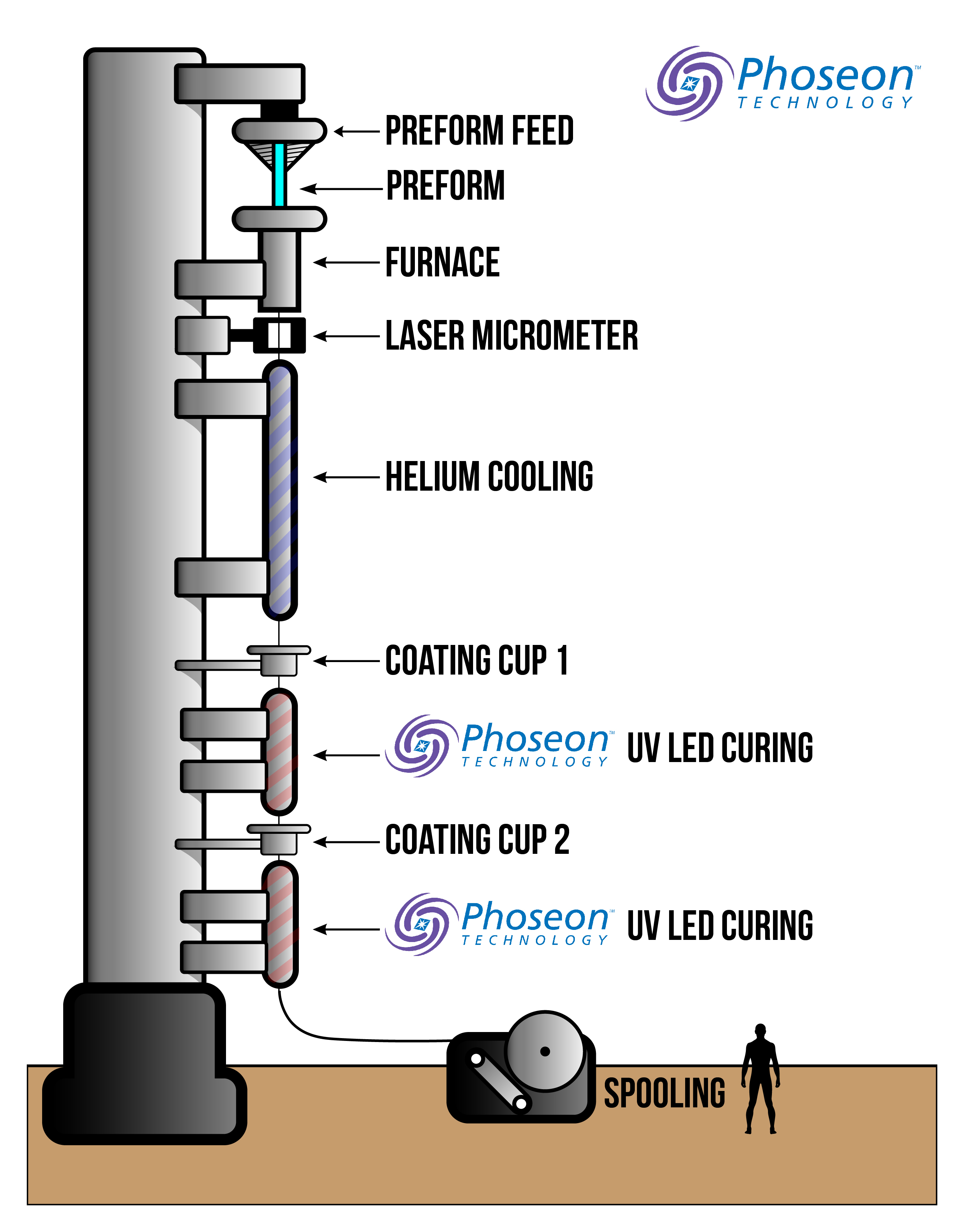

Phoseon Technology’s Fiber Curing System consists of a high intensity UV LED light source, which cures the coatings protecting the glass fibers, along with a patented Fiber Reflector Unit (FRU) to direct the UV energy uniformly around the circumference of the fiber. The UV LED light source and FRU are enclosed in an IP52 enclosure, protecting the system from liquid spills. LED technology drastically reduces energy consumption and significantly reduces operational costs and maintenance downtime. For applications where process monitoring is required, the FRU includes a mounting feature for an irradiance monitoring system.

The latest generation of Fiber Curing Systems features an improved air-flow design to increase internal cooling and reduce fan noise. Mounting hardware integrated into the enclosure makes retrofitting onto existing towers easier than ever. The field proven, fiber optimized UV LED light source paired with the patented focusing reflector provide concentrated UV light energy within a tight cylinder at the fiber draw line, creating ultra-high intensity for maximum curing at the highest speed.

Advantages over Mercury UV:

- Reduced energy – up to 50% or more

- Reduced infrastructure – exhaust, air-exchange, power delivery, no roof penetration

- Elimination of lamp related consumables: bulbs, shutters, reflectors

- Improved safety and environmental – no Hg, no UV-B, no UV-C, no ozone

- Requires less preventative maintenance time

- Reduced equipment failures

- Increased yield due to tighter process control

- Faster process speed

Learn more about UV LED Curing Solutions for Fiber Optics