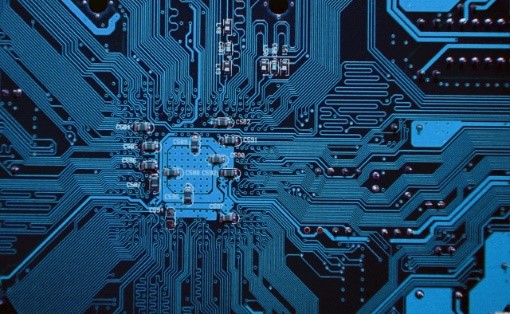

UV LED curing technology is a great fit for printed electronics in applications such as conformal coatings, display coatings and adhesives.

UV LED offers significant advantages over traditional UV curing for printed electronics, including less space, maintenance and downtime which translates into higher productivity rates, less scrap and higher quality end products at lower costs. The use of traditional UV lamps to cure coatings on heat-sensitive substrates such as PCBs and flexible plastics can result in deformation. UV LEDs produce significantly less heat, enabling coating of heat-sensitive substrates. Due to narrow, high UV-A wavelength, UV LEDs produce significantly less heat. This high UV-A wavelength also allows for a more penetrative cure which is an advantage when faced with thicker sections.

Advantages over Mercury UV:

- High UV-A wavelength will reduce heat related damage to materials and substrates

- High UV-A is excellent for curing thick sections

- Controllable power output

- Instant On/Off

- Available in 385/395/405nm

Learn more about UV LED Curing Solutions for Printed Electronics Applications