UV curing is a photopolymerisation process that uses UV energy to change a liquid to a solid. Upon absorption of the UV energy, the photoinitiator (Pl) produces free radicals, which initiate cross-linking with binders (monomers and oligomers) in a polymerization reaction to cure or solidify the ink.

A photoinitiator is any chemical compound that decomposes into free radicals when exposed to light. These special additives ensure that an ink or varnish film is fully cured within a short time on exposure to light. Photoinitiators need light or high energy UV radiation, in order to trigger the polymerization process.

INKS FORMULATED FOR UV LED

Ink formulation for UV LED technology has evolved significantly and, today, there are a growing number of suppliers developing inks that work well with UV LED light sources. One of the key ingredients in the chemical formulation is a photoinitiator that reacts to the narrow wavelength spectrum UV LED energy.

With the continued widespread acceptance of UV LED systems, availability of suitable base materials continues to grow. The driving factors in advancement of chemistry of raw materials are increased capability and cost effectiveness of commercially available UV LED light sources. New resins, monomers, oligomers and photoinitiators are continuously under development. Not only inks but also coatings and adhesives are now widely available that are either specially formulated for LED or work with both LED and traditional mercury sources.

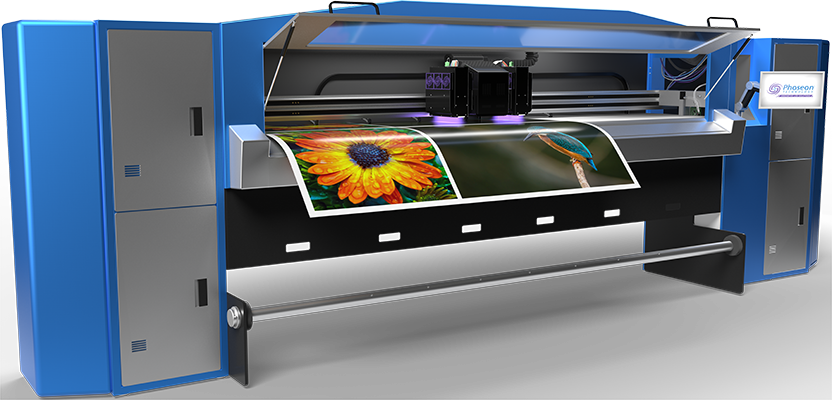

As the technology has become more powerful and more compatible inks are available, this has resulted in substantial advanced capabilities for UV printing. Material suppliers have responded to the demand and challenge from the printing world to formulate raw materials that absorb energy corresponding to the wavelength of UV LED light sources.

Users report that UV LED curing light sources with formulated UV LED inks produce better cures and better adhesion on a wide range of materials, including recycled materials. They can also achieve higher speeds with black and white inks. Tough opaque whites and dense blacks are much easier to cure. UV metallic range inks are stable and print well. Inks do not cure prematurely when exposed to overhead lighting.

AVAILABLE INKS

Today, virtually all large ink suppliers offer products compatible with UV LED light sources. UV LED inks are available for digital, screen, flexo and offset printing applications.

Dozens of companies offer UV LED compatible inks, coatings and raw materials, including: AcromaPro, Agfa, Allnex, BASF, Chimigraf, Collins Inkjet, Deco-Chem, Flint. lmTech, Ink Mill, INX, Kuei, Lamberti, Makiewicz. Marabu, Nazdar, Paragon Inks, Pelikan, Ruco, Sherwin-Williams, Siegwerk, SunJet. Triton, Wikoff and many more.

Here are some examples:

• Flint Group offers the EkoCure eco-friendly, high-performance inks for flexographic and rotary screen printing that are also backwards compatible with traditional UV.

• Agfa's Agora ink systems are free of solvents and VOCs and can be used for industrial decorative printing.

• Nazdar has developed a wide range of inks for use with UV LED curing technology for digital, screen and narrow web printers.

• Paragon Inks in the UK has released an ultra-low migration (ULM) LED range.

• The German ink-maker Ruco offers screen-printing inks that are free from toxic solvents and comply with a European directive for toy safety.

• Marabu offers Ultrapack LEDC series for rotary or flatbed screen printing.